Norafin Reinforcement and Surfacing Veils

Production of Fiber-Reinforced Plastic Profiles

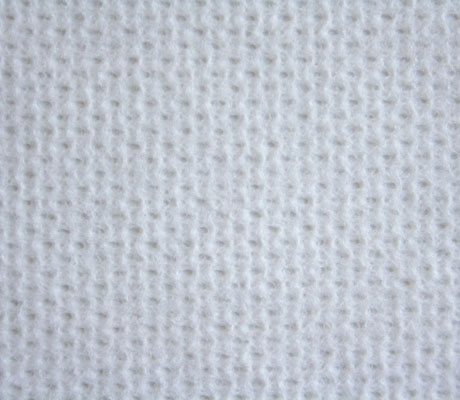

Our polyester-based technical nonwovens ensure that you get optimal surface coverage of your composite.

Pultrusion is a dynamic process in which the reinforcing material, after passing through a resin bath, is drawn through a tool (tempered mold) to produce a consistent product. Because the process is dynamic, inserting a surface mat is an optimal way to provide the composite with a wide range of surface properties.

End Uses:

- composite in wind turbines

- carrier material in manhole covers

- pultruded profiles in chemical plant construction, window construction, building construction, lightweight construction

Performance Characteristics of our Products:

- high-quality surface finish

- reduced reinforcement print through

- elimination of surface penetration of reinforcing fibers

- improved corrosion resistance

- improved resistance to UV discoloration and degradation

- surface conductivity

- improved wear and impact resistance

In addition to the enhanced properties of the pultruded profile, a synthetic surfacing veil such as those manufactured by Norafin also improves the pultrusion process itself giving:

- reduced die wear

- reduced pulling forces

- increased line speeds

The use of a surfacing veil with isotropic properties also gives a significant degree of hoop strength to pultruded profiles such as tubes, 'L' sections and 'U' channels where the main reinforcement is unidirectional.

Possible Product Modifications:

- white/black polyester based synthetic veils for general purpose GRP pultrusions

- polyester-based synthetic veils with tailored levels of conductivity for profiles such as cable trays and ladders, mining ducts, support and access structures in petrochemical and offshore plants etc., which require surface antistatic properties

- para-aramid veils for improved impact and wear resistance

- pre-ox based veils for enhanced fire resistance

- available in various basic weights

- widths upon request

Your Contact Persons

Jeff Henkemeyer

Sales Manager Protective and Performance Line

| T: | +1 828 435 7044 | |

| M: | Jeff.Henkemeyer@norafin.com | |

| LinkedIn profile | |

Tim Natzschka

Product Manager Performance Line

| T: | +49 3733 5507 294 | |

| M: | Tim.Natzschka@norafin.com | |

| LinkedIn profile | |