Norafin Crystalen® – Air Dedusting Spunlace Filter Media

Norafin offers a wide range of spunlaced filter media for air dedusting for regular temperature applications and high temperature ranges. Due to our many years of expertise, we can process a wide variety of technical fibers in application-specific combinations.

- temperatures below 130 °C: Bi-Component fibers (Bico), PET, PAN, PA

- temperatures above 150 °C: PPS, meta-aramids, PI, PTFE

End Uses:

- mineral, cement, asphalt industry

- metal and wood processing

- industrial waste and biomass incineration

- food industry

Performance Characteristics of our Products:

- high efficiency of spunlaced nonwovens at low weights compared to needlepunched nonwovens:

- 320 g/m² as more efficient alternative to 400 g/m² needlepunched nonwoven

- 370 - 450 g/m² as more efficient alternative to 500 - 550 g/m² needlepunched nonwoven

- better cake release due to an even surface

- high filtration efficiency at low pressure difference according to VDI 3926-II:2004

- high durability

- reduced energy consumption

- high-temperature resistance up to 240°C

- flow rates from 50 – 3000 l/dm²/min

- antistatic

Our possible product modifications

Since our fabrics can be individually engineered to improve cleaning characteristics, mechanical stability and dust holding capacity, we can always match specific client needs regarding product attributes and efficiency.

Be it in process air or dust filtration, HVAC or process liquid filtration, it is our aim to transform your need into the right product concept and offer a durable solution that supports a safer life.

Processing of different fibers and fiber blends:

- temperatures below 130 °C: Bi-Component fibers (Bico), PET, PAN, PA, PP, viscose

- temperatures over 150 °C: PPS, aramids, PI, PTFE, Ox-PAN

for covering a wide range of temperature and chemical resistance.

- spunlaced filter media (30-500 g/m²) for ideal filtration efficiency vs. flow rates:

- provides more surface and fine filtration

- very dense structures

- needlepunched filter media (30-900 g/m²) for ideal dust holding capacity

- provides more depth filtration

- voluminous structures

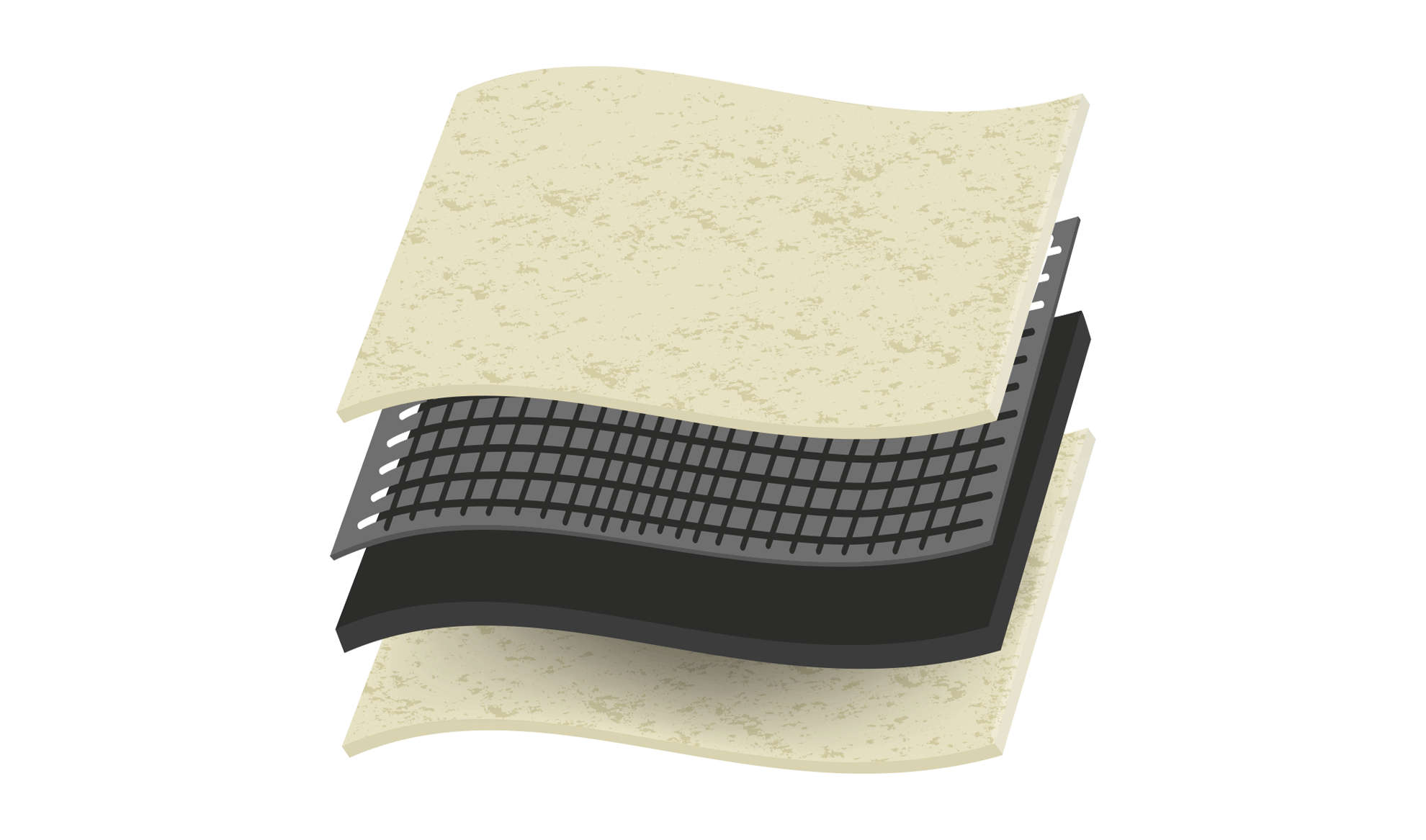

- hybrid structures, that combine spunlaced and needlepunched nonwovens; multi-layer constructions

- with or without support structure

- TOP Layer-Technology: surface oriented filtration layer / membrane-like effect layer

- multi-layer-technology: integration of metallic layers possible

We can supply our customers with roll widths from 100 mm min. up to 2300 mm max.

- impregnating:

- water- and oil repellency

- flame-retardant

- reinforcement/stiffening

- calendering:

- surface modifications

- foam application:

- stable/unstable

- lamination

Since our fabrics can be individually engineered to improve cleaning characteristics, mechanical stability and dust holding capacity, we can always match specific client needs regarding product attributes and efficiency.

Norafin ECOLINE®

The use of renewable raw materials is important to us in terms of sustainability of our production chain.

In the sense of the Circular Economy and only, where permitted by the final application, we can provide the use of recycled fibers to our customers.

In our Filtration Line, the use of recycled PET plays an important role. Thanks to our in-house technology we are also able to recover high-performance fibers such as aramids.

Please contact us to learn more about our sustainable solutions for filtration.

Downloads

Your Contact Persons

Tobias Thiem

Product Manager Filtration Line

| T: | +49 3733 5507 262 | |

| M: | Tobias.Thiem@norafin.com | |

| LinkedIn profile | |

Kevin Fiedler

Sales Manager Filtration Line

| T: | +49 3733 5507 264 | |

| M: | Kevin.Fiedler@norafin.com | |

| LinkedIn profile | |